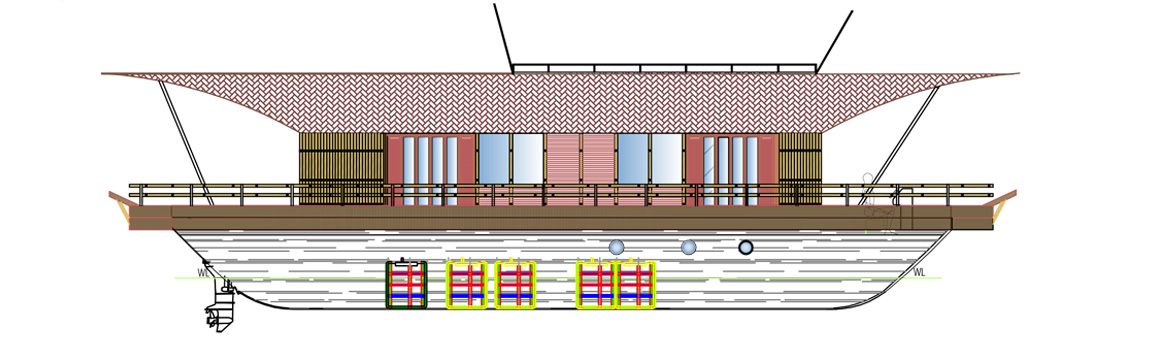

76FT. CATAMARAN HOUSE BOAT

General Specification & Standard Outfitting

|

|

DIMENSIONS |

|

|

|

||

|

|

Length Overall |

76 Ft |

Length over hull |

72 Ft |

|

|

|

Breadth hull |

23 Ft |

|

|

Breadth over Roof |

27 Ft |

Displacement (loaded) |

43.4 Tons (Approx.) |

|

Draught (loaded) |

2’ 6” |

|

Passenger Capacity |

8-10 pax with 2 crew |

|

Fuel Capacity (Petrol) |

250 Ltrs |

|

Fuel Capacity (Diesel) |

500 Ltrs |

|

Fresh water capacity |

4000 Ltrs |

|

Black water |

1000 Ltrs |

|

Grey water |

2000 Ltrs |

|

Outboard Motors |

2 x 40HP (40 ATL) (4 stroke) Suzuki Petrol |

|

|

|

||

DESIGN

Vessel is been built as per the Design, Drawings and Specifications Provided by Architect Sunela Jayewardene Environmental Design (pvt) Ltd; with required changes made by the builder in agreement with architect to meet requirements of Fiber Glass boat construction.

CONSTRUCTION DETAILS

2.1) Hulls

Hulls to be moulded out of LR approved GRP materials.

Hulls to be moulded out of LR approved GRP materials.

Hulls are to be adequately reinforced and anchored together with a structural steel trusses frame work.

Hulls are to be adequately reinforced and anchored together with a structural steel trusses frame work.

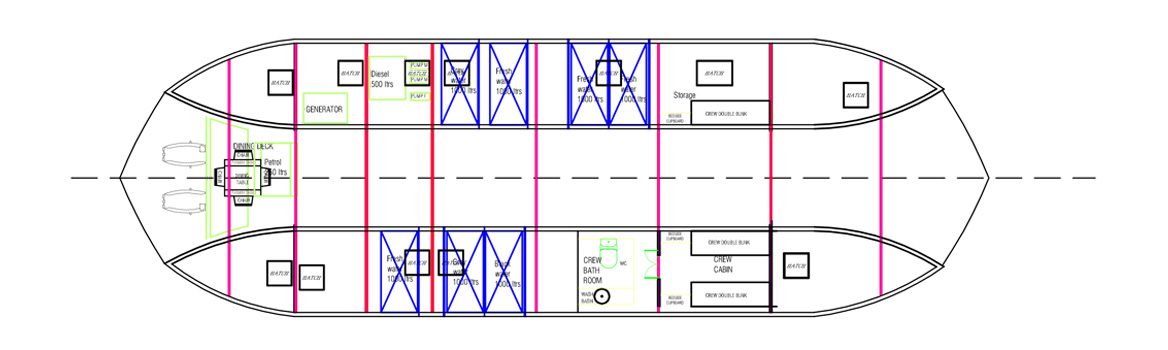

Hulls are divided in to watertight compartments to maintain damage stability

Hulls are divided in to watertight compartments to maintain damage stability

All tanks are integrated to hulls with necessary fittings and gauges.

All tanks are integrated to hulls with necessary fittings and gauges.

Water tanks inside are applied with food grade resin.

Water tanks inside are applied with food grade resin.

Exterior hull color is to be customers’ choice as per availability of colurs.

Exterior hull color is to be customers’ choice as per availability of colurs.

Underwater area will be applied with anti fouling.

Underwater area will be applied with anti fouling.

All fasteners used will be suitable for saline environment.

All fasteners used will be suitable for saline environment.

2.2).Deck and House structure

Plywood deck will be fitted on steel structural frame work with suitable timber scantlings. kiln seasoned Ceylon Teak planks tongued and grooved will be layed over exterior plywood deck with a bedding and and fixed with fastenings.

Plywood deck will be fitted on steel structural frame work with suitable timber scantlings. kiln seasoned Ceylon Teak planks tongued and grooved will be layed over exterior plywood deck with a bedding and and fixed with fastenings.

Hardwood timber bow Sprit fitted to fwd & aft decks as shown on the General Arrangement Drawing.

Hardwood timber bow Sprit fitted to fwd & aft decks as shown on the General Arrangement Drawing.

3”x3” Steel vertical side pillars will be extended up to the roof to support structure and intergrated to build the deck house.

3”x3” Steel vertical side pillars will be extended up to the roof to support structure and intergrated to build the deck house.

Steel Pillars will be fixed to the deck structure.

Steel Pillars will be fixed to the deck structure.

Top Roof structure will be out of G.I pipes strusses bolted to the sides steel columns.

Top Roof structure will be out of G.I pipes strusses bolted to the sides steel columns.

Top Roof covered with glass fibre sheets laid over with cadjan. Sides steel structure side panelling is insulated with polystyrene panels on both sides allowing an air gap in the middle. Polystyrene panels are cladded and boxed on the out side and inside with cement plaster board painted matt black.

Top Roof covered with glass fibre sheets laid over with cadjan. Sides steel structure side panelling is insulated with polystyrene panels on both sides allowing an air gap in the middle. Polystyrene panels are cladded and boxed on the out side and inside with cement plaster board painted matt black.

Outer plaster board is cladded up to roof structure with polished Lunumidella strips of 1”x0.5” length wise with a 1” black line between the strips

DeckHouse interior walls are to be covered with woven Teak veneer ply.

DeckHouse interior walls are to be covered with woven Teak veneer ply.

Flooring inside the deck house layed with Eucalyptus planking. Timber removable Teak grating provided on toilet flooring.

Flooring inside the deck house layed with Eucalyptus planking. Timber removable Teak grating provided on toilet flooring.

Door and window frames will be of mahogany timber with louvered type doors and windows fitted with glass panels as shown on GA drawing.

Door and window frames will be of mahogany timber with louvered type doors and windows fitted with glass panels as shown on GA drawing.

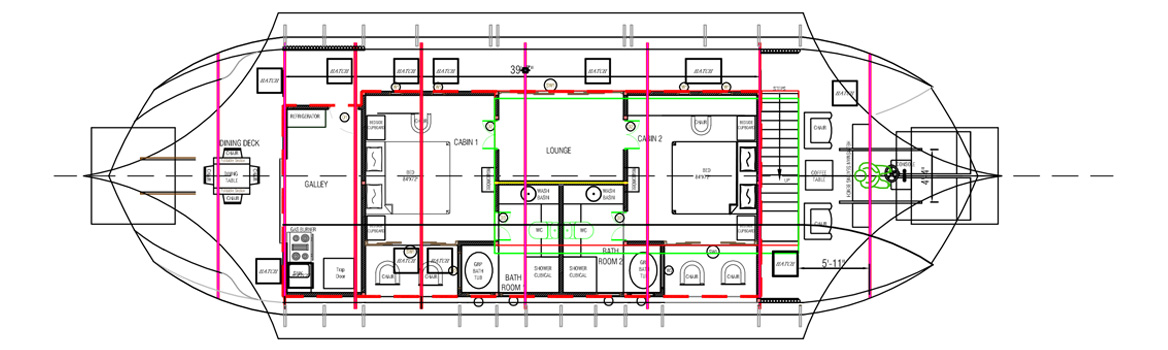

2.3) General Arrangement

Fwd. Deck

Helm area fitted to front with a helm console fitted with steering Wheel, engines controls and instrumentation and a helmsman bench type seating. Aft of helm area a coffee table and foldable chairs provided for guest seating on the deck. Staircase to the upper deck is fitted aft of seating area against the deck house front wall.

Deck House

Floor to ceiling height inside would be 8 Feet. Inside of deck house is living area consistng of two guest rooms on either side with a lounge area provided to centre with main entry doors to lounge from deck port side. Entry to guest rooms are from the lounge. Inside of each guest room consist one double bed 7ftx6ft (LxW) with 12inch foam mattress,two bedside cupboards with table top/drawer unit where bed lamps would be kept. Provision provided for hanging of clothing and a single chair.

Separate wash rooms are provided in each guest room with lockable entry door for privacy and inside fitted with a WC, wash basin counter top and wall mirror. A balcony with sitting area provided outside each guest room to starboard deck with opening from the room. Two chairs provided in each room balconies for seating. Windows are fitted to room side wall as shown on GA Drwg. Kitchen with provision for fitting of kitchen equipment and sink with fresh water supply fitted on aft of the living area with entry door from deck side port. Kitchen area fitting of equipment and cupboards etc., will be carried out by the customers’ selected supplier. As power requirement of the generator is worked out only for the lighting and other standard appliances such as fans pumps etc, the stove to be used will have to be of LP gas burners type. Provision will be made for a gas locker outside under the deck with access from above ventilated to out side. Gasline will be layed from the gas locker up to the cooker. Kitchen layout is worked out as per customer requirements.

Aft deck

Two dining tables with four chairs will be provided on the teak plank layed aft deck.

Roof Top Balcony

Top roof balcony provided on top of deck house with entry steps up from deck below. Wooden safety rails mounted on brass upright stanchions is to be fitted around the balcony. A foldable canopy at Height of 6 ft. would be provided partially covering covering roof deck.

Crew Accomodation

Crew accomodation provided below deck inside of port side hull with entry through a deck hatch. Two bunk beds with lockers and a toilet fitted with a WC, shower and wash basin provided for the crew. Provision will be kept on the floor to access to the Hull Machinery.

2.4) Windows and Doors

Fitted as shown on the GA drawing in the deck house.

2.5) Ceiling

Ceiling inside of deck house living area will be of woven Dumbara Mats (Dumbara Mats will be supplied by the buyer.)

Ceiling inside of deck house living area will be of woven Dumbara Mats (Dumbara Mats will be supplied by the buyer.)

Soffit mounted down lighting will be fitted.

Soffit mounted down lighting will be fitted.

Provision kept inside to carry AC ducting and electric cables.

Provision kept inside to carry AC ducting and electric cables.

VESSEL SYSTEMS AND EQUIPMENTS

3.1). Deck fittings & mooring

4 Nos of stainless steel bollards fitted on port and starboard deck fwd and aft.

4 Nos of stainless steel bollards fitted on port and starboard deck fwd and aft.

Wooden capping fitted around the deck edge.

Wooden capping fitted around the deck edge.

02 nos. of mooring rope will be provided. (18 mm x 10mtrs).

02 nos. of mooring rope will be provided. (18 mm x 10mtrs).

02 nos. Steel galvanized anchor of approx.17 kg each.

02 nos. Steel galvanized anchor of approx.17 kg each.

3.2). Powering and manoeuvring

Vessel will be powered by twin Suzuki 40Hp petrol outboard motors fitted on transom well with manual hydraulic steering.

Vessel will be powered by twin Suzuki 40Hp petrol outboard motors fitted on transom well with manual hydraulic steering.

If maneuverability and turning problems are encountered during trials suitable size Bow and Stern thrusters are to be fitted (extra not included on the quoted boat price)

If maneuverability and turning problems are encountered during trials suitable size Bow and Stern thrusters are to be fitted (extra not included on the quoted boat price)

3.3). Fuel system

Fuel tanks for generator and OBM will be placed under the hulls and well ventilated fitted with necessary fillers and guages.

Fuel tanks for generator and OBM will be placed under the hulls and well ventilated fitted with necessary fillers and guages.

All fuel hoses will be of suitable type to carry diesel and petrol.

All fuel hoses will be of suitable type to carry diesel and petrol.

3.4). Bilge system

Required number of submersible bilge pumps will be fitted in two hulls for bilges emptying.

Required number of submersible bilge pumps will be fitted in two hulls for bilges emptying.

3.5). Fresh water system

Interior surfaces of the tanks will be applied with food grade resin.

Interior surfaces of the tanks will be applied with food grade resin.

Tanks fitted with level gauges.

Tanks fitted with level gauges.

Fresh water system will be fitted with 230 A.C pressure pump of suitable capacity to supply uninterrupted water supply to all required outlets.

Fresh water system will be fitted with 230 A.C pressure pump of suitable capacity to supply uninterrupted water supply to all required outlets.

Installation of solar panels on the boat roof and installation of water tank inside (Solar/heater) Size of solar panel and tank capacities are to be indicated. (Option not included in quoted vessel price) upon later.

Installation of solar panels on the boat roof and installation of water tank inside (Solar/heater) Size of solar panel and tank capacities are to be indicated. (Option not included in quoted vessel price) upon later.

3.6). Black and Grey water systems

Black and Grey water systems consist of storage tanks placed and secured inside of the hulls.

Black and Grey water systems consist of storage tanks placed and secured inside of the hulls.

Systems equipped with level gauges and vents and outlet points on deck side.

Systems equipped with level gauges and vents and outlet points on deck side.

Tanks can be emptied through the electric macerator pumps fitted to system.

Tanks can be emptied through the electric macerator pumps fitted to system.

ELECTRICAL SYSTEM

4.1) 230 V/50 HZ AC Electrical systems

Main electrical system of the vessel will be powered by a marine water cooled generator of capacity of approx. 14 KW.

Main electrical system of the vessel will be powered by a marine water cooled generator of capacity of approx. 14 KW.

Generator will be placed in the hull in a well ventilated a sound insulated compartment.

Generator will be placed in the hull in a well ventilated a sound insulated compartment.

Generator exhaust is wet type exhaust with muffler.

Generator exhaust is wet type exhaust with muffler.

Generator will supply the power to lighting, fresh water pump, fans and AC power outlets for standard electricity consumable house appliances.

Generator will supply the power to lighting, fresh water pump, fans and AC power outlets for standard electricity consumable house appliances.

4.2) Lighting

Lighting and power points will be provided as follows.

230 volt AC

Lighting and power points will be provided as follows.

230 volt AC

Fwd. Deck

02 nos. soffit mounted down light on roof canopy

01 no. Wall mounted lights 01 no. 5 amp power point

Aft Deck

01 no. Pendant light fitted above dining table

02 nos. Wall mounted lights fitted to aft wall

Side decks

(port) 05 nos. Down lights fitted to roof canopy

01 no. 5Amp power point

Lounge

01 no. Down light fitted to ceiling

04 nos. Wall mounted lights

02 nos. 5 Amp power out lets

Guest rooms

01 no. Pendant light

02 nos. Wall mounted lights

03 nos. 5 Amp power outlets

Guest room balcony

01 no. Wall mounted light

01 no. 5 Amp power outlet

Guest room toilets

01 no. Down light

01 no. 5 Amp power out let

01 no. 13 Amp power points fitted only if electric geysers are required

Kitchen

02 nos. Down lights

03 nos. 5 Amp power outlets

Crew cabin

02 nos. Wall mounted lights

01 no. 5 Amp power outlets

Top Deck

02 nos. 5 Amp Power outlets

Additional plug outlets will be supplied where pedestal fans are to be kept

12 volt DC outlets will be provided only as required. Wiring provided for an integrated music system and Power supply will be provided for I pod sockets in bed room and Lounge.

Power supply to A WIFI Router

4.3) 12 volt DC system

2 x 90AH batteries provided to supply the required power for two

2 x 90AH batteries provided to supply the required power for two

Outboard engines and will be charged by OBM in built alternators.

Outboard engines and will be charged by OBM in built alternators.

01 No. x 200 Amp battery will be fitted additionally to power the bilge pumps and navigation lights. This battery will be charged by the onboard battery charger with splitter as well from the Generator or and 230volt shore power supply. Navigation lights will be of 12 volt DC

01 No. x 200 Amp battery will be fitted additionally to power the bilge pumps and navigation lights. This battery will be charged by the onboard battery charger with splitter as well from the Generator or and 230volt shore power supply. Navigation lights will be of 12 volt DC

4.4) Air-Conditioning of ground floor

Following standard split type air cooled AC units will be fitted.

2 x 9000 Btu/Hr each in the Guest Rooms.

1x 12000Btu/Hr in the lounge area.

13 amp power sockets is to be provided for each air-conditioning unit

PAINTING AND FINISHING

Hull Fibre Glass surface to be of perfect mould finish. All interior hull surfaces are to be coated with a top coat.

Hull Fibre Glass surface to be of perfect mould finish. All interior hull surfaces are to be coated with a top coat.

Interior and exterior timber work to be applied with a minimum of two coats of water based exterior lacquer.

Interior and exterior timber work to be applied with a minimum of two coats of water based exterior lacquer.

TRIALS

On completion, vessel trials are to be carried out in the presence of the owner’s representatives on board.

Owner is to provide the builder, required facilities to carry out the trials.

LAYOUTS

EXTERIOR/INTERIOR

http://neilmarine.com/index.php/76ft-catamaran-house-boat#sigFreeId52f748d4e4

0

0 1

1 2

2