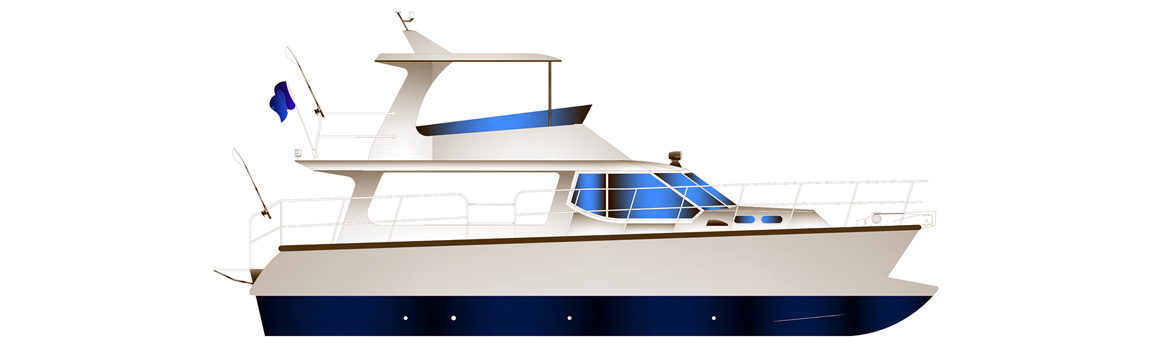

44 FT. DIVE EXCURSION / PASSENGER TRANSPORT CAT

General Specification & Standard Outfitting

|

|

DIMENSIONS |

|

|

|

||

|

|

Length overall |

44’ - 00” (13.35 Mtrs) |

Beam over hull |

15’ - 05” (4.70 Mtrs) |

|

|

|

Draught (laden) |

3’ - 02” (0.975 Mtrs) |

|

|

Displacement (laden) |

9.9 Tons |

Fuel Capacity (Petrol) |

750 Litres |

|

Fuel Capacity (Diesel) |

250 Litres |

|

Water Capacity |

500 Litres |

|

Black Water Capacity |

150 Litres |

|

Seating capacity |

20 Passengers + 3 crew |

|

Speed max |

18-20 knots |

|

Propulsion |

Twin Mercury Verado 200HP 4-Stroke OBM Engines |

|

Generator |

Caterpillar C1.5, 12KW Marine Diesel |

|

|

|

||

PART ASSEMBLY

1.1 Design concept

This craft is a high speed symmetric catamaran hull. The hull shape has been optimized for speed in conjunction with good sea-keeping and a comfortable ride whilst retaining a shallow draft capability.

1.2. Hull Construction

The hull is moulded in GRP using hand layup constructed from Lloyds registered classification approved Chopped strand mat, woven roving and polyester resin. The hull is stiffened by a system of polyurethane transverse frames and longitudinal stringer structure glassed to the hull according to the Lloyd’s Register rules and regulations.

1.3. Deck Construction

The deck is moulded out of GRP non-slip surface finish reinforced with balsa core. The deck is stiffened by a system of polyurethane transverse frames and longitudinal stringer structure glassed to the deck.

1.4. Wheelhouse and Fly-bridge

The wheel house is moulded out of GRP and reinforced with polyurethane stringers glassed to the shell. Aft centre door provided to access the aft deck. Sliding windows are provided PORT and STBD sides as shown in the G.A and five front windscreens are provided for all-round good visibility. Main door will be of aft bulkhead with entrances to the aft deck. Entry to the fly bridge will be through a staircase located in the wheel house.

1.5. Main Bulkheads

Main bulkheads are to be constructed out of WBP and BS 1088 plywood glassed on Transverse PU foam frames to retain watertight integrity.

1.6 Fuel Tank

The fuel tanks for the Outboard Board Engines will have a total capacity of 750 (2X375) Ltrs and will be made of ALUMINUM and placed under the deck with filler, vent, sight gauge and inspection cover. The Tanks will be placed to the Forward of the Outboard engines on PORT and STBD sides. A separate GRP tank with a capacity of 250 Litres will be provided to hold the Diesel that will fuel the Generator.

1.7 Water Tank

The Fresh water tank with a capacity of 500 Ltrs will be made up of GRP and placed under deck with filler, vent, sight gauge and inspection cover. Pressure water outlet will be provided at the toilet, the Galley and Aft-deck shower.

1.8 Black Water tank

The black water tank with a capacity of 150 Ltrs will be made up of GRP and placed under deck with vent, sight gauge and inspection cover. A Macerator pump is provided the pump the waste water out of the boat.

EXTERIOR FIT OUT

2.1 Mooring Equipment

- 10” cleats will be placed on PORT and STBD sides on Fore Deck and Aft Deck. Total 4 No’s have been provided.

- 4 Units Stainless steel mooring bollards have been fitted on PORT and STBD sides on Fore and Aft Deck as shown in General Arrangement Drawing.

- Kobra 900Kg Max Pull Capacity with Hauling speed of 20Kg/min (50Kg load) Including a 2-way relay, fuse and breaker along with 2 station control (foot switches on fore deck and Main Console inside the wheel house) along with a stainless steel bow roller and 15kg galvanized steel anchor have been fitted on the fore deck.

- Additional 15Kg Galvanized Steel Anchor has been provided.

- 8mm Galvanized Steel short link chain (31 Mtrs) provided.

- 14mm P.P. Rope 30m Long has been provided.

- 2 Units 18mm Mooring Rope 10m long have been provided.

2.2 Fender

Heavy duty “D” type rubber fender to fit around the gunwale. 5 inflatable rubber fenders have been provided.

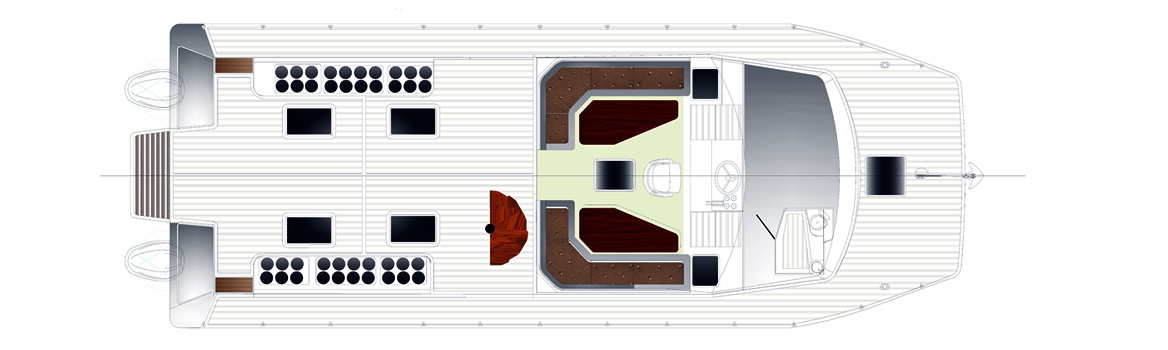

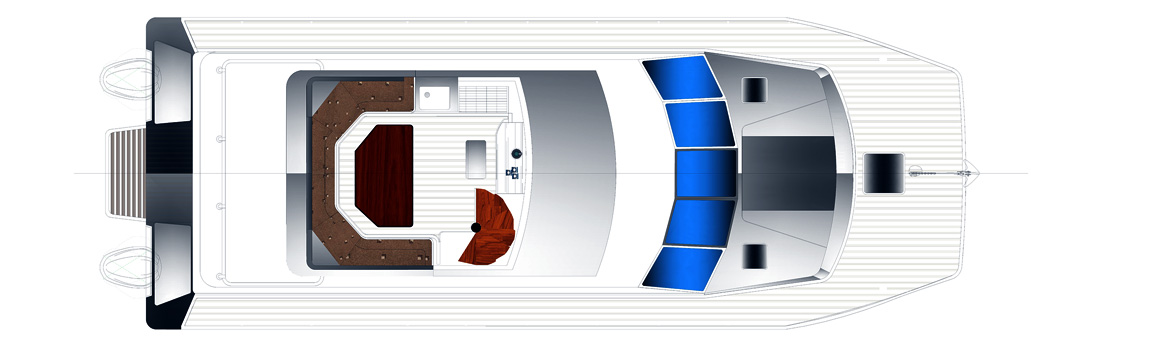

3.1 Deck

As Shown in the G.A Drawing deck fittings are fitted and railing fitted right around. The side-walk and fore-deck along with the fly-bridge floor has been laid with Ceylon teak. The floor aft of the cockpit has a non skid finish. Loop pile carpet has been used to cover the floor inside the cockpit. The galley floor has been laid with Ceylon teak.

3.2 Wheelhouse

Cockpit Area

Helm position and console is provided to front centre with steering wheel, engine controls and instrumentation within easy reach of the helmsman. A 24000BTU Marvair air-conditioner has been fitted inside the cockpit with vents. Lounge seats have been provided on both PORT and STBD sides with a fibreglass table which when lowered acts as a base when converting the seats into beds. The ceiling inside the cockpit has been covered using Vinyl fabric.

Aft. Cockpit Area

Fiberglass cushion seats with back rests have been provided on both PORT and STBD sides. Compartments have been provided below the seats to store 40 scuba tanks. The staircase has been placed on the STBD side and a fibreglass compartment has been made for the air compressor used to fill the scuba tanks. Hatches have been placed to enter the fuel tank compartments, generator compartment and the battery compartment. Fuel fillers and water fillers have been placed on the side walk.

3.3 Fly Bridge

The fly bridge consists of a U-shaped couch and a table along with sink, tap a Barbeque grill and a Mini fridge. The Barbeque grill is placed inside a compartment which can be locked. The grill is placed on a stand which can be lifted or lowered to meet with the safety requirements set by the grill manufacturers. A console will be provided on the upper deck for control of the boat in the center forward area of the fly-bridge. Entry to the upper deck will be through a U shaped staircase which will be located in the STBD side of the boat in the mid-ship area.

3.4 Toilet

Fully functional western style toilet has been provided with a sink, tap and a pull out shower. The toilet is located in the forward section of the boat on the STBD side. Entry to the Toilet will be through a staircase in the forward section of the wheel house

3.5 Galley

The galley is located in the forward section of the boat on the port side. Entry to the Galley will be through a staircase in the forward section of the wheel house. The galley will consist of Gas Stove, counter top and sink. The Mini fridge is located below the counter top.

ELECTRICAL

4.1 Electrical system

12V DC system with following navigational lights and standard lighting. a. Remote control Search light b. Battery charger with shore power connection. Wiper Three No’s to Fit on Helm screen

4.2 Batteries

4 Batteries will be provided.

Type - 12 volt x 200 Amp-hr lead acid type – 3 Units

12 volt X 90 Amp-hr lead acid type – 1 Unit

Batteries are to be charged by alternator and battery charger. Battery charger will be provided to charge the batteries by shore supply when vessel is berthed and by Generator when the vessel is at sea.

4.3 Navigational Lights and equipment

1 No Port

1 No Starboard

1 No Stern

1 No Mast Head Light

1 No Anchor Light Port and starboard lights mounted on fwd deck. Stern light will be mounted on aft of the deck. Compass 3 ½” Card Dia. 1 No

Garmin GPS (Optional) 1 No

Bulk Head Lights 13 No’s

PLUMBING SYSTEM

Bilge System Bilge Pumps No 8

Type 12V electric submersible bilge pumps of 1500 Gls/per Hr. are fitted all water tight compartments.

With separate discharge ports

ENGINE / STEERING

6.1 Propulsion

2 X 200 HP 4 STROKE Mercury Verado OBM

6.2 Steering

Manual Hydraulic steering system fitted with wheel at Console on deck and fly-bridge as with standard controls.

LIFE SAVING AND SAFETY EQUIPMENT

Life Ring 75 mm Outer Diameter 04 No’s Life Jackets for Adults 24 No’s First Aid Locker (Optional) 01 No

FIRE FIGTHING EQUIPMENT

Fire Extinguishers 06 No’s

Make fire master (BSEN3”1996)

MATERIAL AND WORKMAN SHIP

All materials, and equipment used are of marine type and suitable for the intended services and to be free of imperfections of manufacture and defects. All fibre glass material used is of best quality material and approved by Lloyds Register of shipping. All fasteners used for construction and assembly of the launch to be stainless steel and brass and where necessary to be galvanized steel.

Painting and Finishing

The vessel will be painted by gelcoating method. Under water areas will be painted with approved quality antifouling. The hull and deck colours will be as per customer requirement and subject to availability.

All stainless steel fittings are polished Furniture joinery work where varnished is to be given not less than 3 coats. All trims will be out of teak trims.

TRIALS AND WARRANTY

Trials The craft will be launched and trialled in the presence of the owner’s representatives on board.

Warranty The Builder will guarantee the vessel for a period of one year commencing from the date of handing over arising from any workmanship or material defects. All equipment and machinery will carry manufacturer’s warranty.

LAYOUTS

EXTERIOR/INTERIOR

http://neilmarine.com/index.php/44ft-dive-excursion-passenger-transport-cat#sigFreeIdc756d0f9be

0

0 1

1 2

2