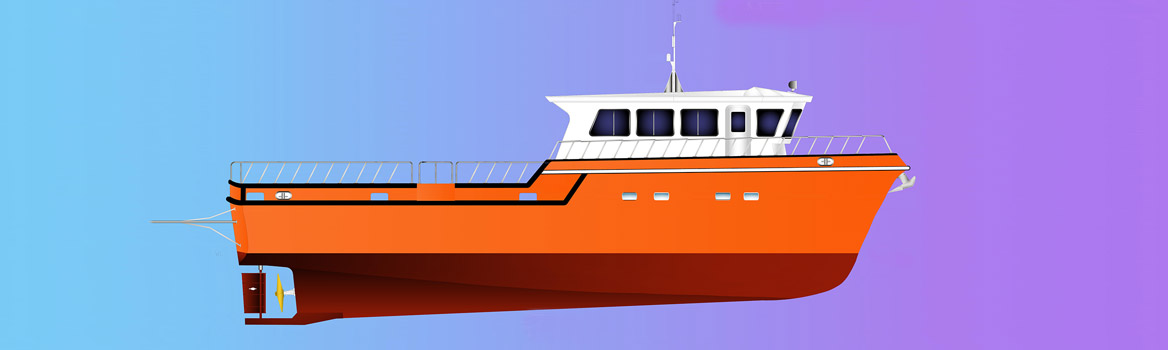

18MTR. HARBOUR WORK BOAT

General Specification & Standard Outfitting

|

|

PRINCIPAL DIMENSIONS |

|

|

|

||

|

|

LENGTH OVER ALL |

18.00 M |

|

|

BEAM |

5.60 M |

|

|

DRAFT (LIGHT) |

2.60 M |

|

|

DISPLACEMENT (UNLOADED) |

26 TONS |

|

|

DISPLACEMENT (LOADED) |

45 TONS |

|

|

FUEL CAPACITY |

9000 LTRS. |

WATER CAPACITY |

3000 LTRS |

|

ENGINE |

DOOSAN MDL V 222 TIH, 720 HP @ 1800 RPM. |

|

SPEED (APPROX.) |

12 – 14 KNOTS |

|

|

|

GENERAL DESCRIPTION

Heavy displacement hull of chine design with a fine fwd entry and flat run aft suitable for operation on all kinds of sea conditions.

Hull is designed by Mr. David Freeman, Naval Architect of Freeward Marine Ltd, United Kingdom

HULL

GRP split molding constructed from Lloyds approval polyester resin, chopped strand mat and woven roving strengthened by low density polyurethane foam frames glassed over.

SHELL MAIN LAYUP

LAY UP ABOVE W/L 5550 G/M2

LAY UP BELOW W/L 6800 G/M2

BULKHEADS

18mm marine grade plywood placed over frames and bonded to the hull.

ENGINE BEDS

Engine beds are of moulded GRP angle sections or high density PU foam glassed over. The beds are glassed to the hull with transverse frame work. The size of the engine bed and position can be altered to any make of engine suitable for this vessel.

GUNWALE

Heavy duty D section rubber fendering fitted to fwd and hard wood timber fender with capping to be fitted around the gunwale for protection and hauling of the nets.

GRP deck reinforced with hard wood transverse frames glassed over and to be bonded to hull. Timber jack planks are fitted over the deck.

DECK CONSTRUCTION

GRP deck reinforced with hard wood transverse frames glassed over and to be bonded to hull. Timber jack planks are fitted over the deck.

DECK CONSTRUCTION

GRP deck reinforced with hard wood transverse frames glassed over and to be bonded to hull. Timber jack planks are fitted over the deck.

WHEEL HOUSE CONSTRUCTION

GRP wheel house with PU core sand witch construction reinforced With stiffeners glassed over and to be bonded to deck.

WHEEL HOUSE MAIN LAY UP TOTAL 1350 G/M2

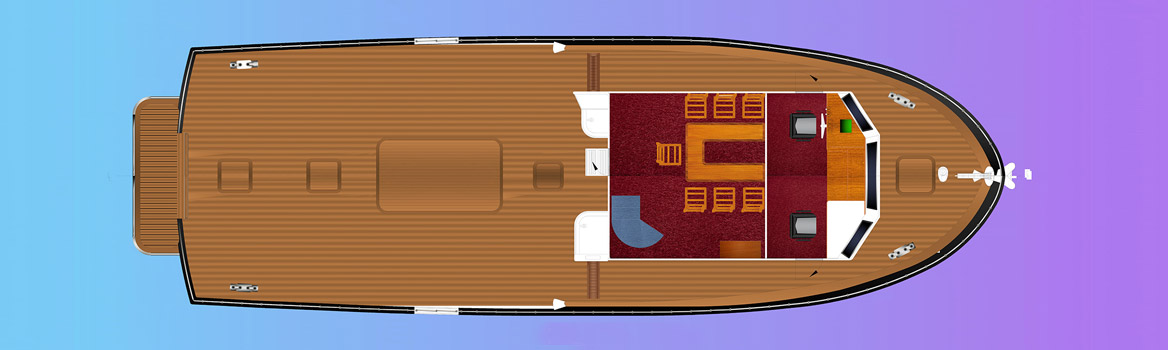

ARRANGEMENT

Fore peak

Fore peak

Fwd accommodation

Fwd accommodation  Engine room/tank bay

Engine room/tank bay  Wheel house

Wheel house

FORE PEAK

Approx. 2.9 M in length.

Approx. 2.9 M in length.  Access by a watertight over head deck hatch.

Access by a watertight over head deck hatch.

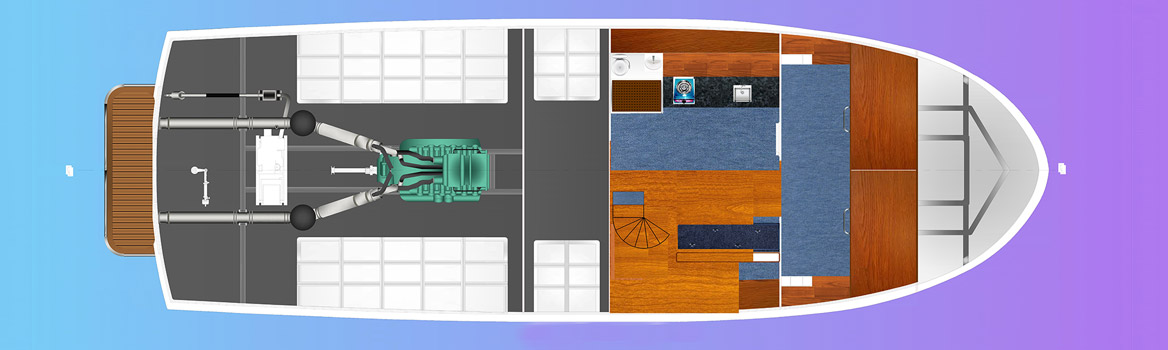

FWD PASSENGER CABIN

Approx. 5.9 M in length.

Approx. 5.9 M in length. Crew accommodation fitted to front with two bunk beds to port and starboard provided.

Crew accommodation fitted to front with two bunk beds to port and starboard provided.  Aft of berth is seating area with table fitted to port side.

Aft of berth is seating area with table fitted to port side.  A toilet and galley are fitted to port. Toilet is fitted with shower, marine WC and a wash basin with fresh water supply.

A toilet and galley are fitted to port. Toilet is fitted with shower, marine WC and a wash basin with fresh water supply. Galley consists of a work top with wash basin, cooker and 6 cubic feet refrigerator. Fresh water supply provided to galley wash basin with a tap.

Galley consists of a work top with wash basin, cooker and 6 cubic feet refrigerator. Fresh water supply provided to galley wash basin with a tap. Spaces remaining underneath of berths and seats on port and starboard hull sides are to be used as lockers.

Spaces remaining underneath of berths and seats on port and starboard hull sides are to be used as lockers.

ENGINE ROOM/TANK BAY

Approx. 9.0 M in length.

Approx. 9.0 M in length.  This compartment consists of main engine, battery boxes, integral fuel and water tanks.

This compartment consists of main engine, battery boxes, integral fuel and water tanks.  Entry to engine room through a lift up sole hatch on deck.

Entry to engine room through a lift up sole hatch on deck.

WHEEL HOUSE

Approx. 6.7 M in length.

Approx. 6.7 M in length.  Wheel house fwd area reserved for helmsman console with helm position to stbd and navigator seats to port. Dining area with seating for 06 persons provided aft of wheel house with centre dining table.

Wheel house fwd area reserved for helmsman console with helm position to stbd and navigator seats to port. Dining area with seating for 06 persons provided aft of wheel house with centre dining table.  Entry to wheel house from port and stbd entry doors and from aft deck.

Entry to wheel house from port and stbd entry doors and from aft deck.

MAIN ENGINE

Doosan Marine Diesel Engine MDL V 222 TIH of 720 Hp @ 1800 RPM complete with Marine hydraulic gear box, stern arrangement and standard accessories.

ENGINE CONTROL

All necessary remote control will be led to the helm position in the wheel house. These will normally include single lever cable type engine controls,engine start / stop controls and warning indications of standard engine panel.

STERN GEAR

The stainless steel propeller shaft run through a brass stern tube fitted with stuffing box, gland water lubrication and cutlass bearings. Manganese bronze propeller to be provided.

VESSEL SYSTEMS

The stainless steel propeller shaft run through a brass stern tube fitted with stuffing box, gland water lubrication and cutlass bearings. Manganese bronze propeller to be provided.

EXHAUST SYSTEM

Wet type exhaust system fitted with water injection bend and goose neck connected to rubber exhaust hose lead through transom hull out let

BILGE SYSTEM

Pumps - One manual hand pump of 140 l /min capacity.

No off Three

Type electric submersible bilge pumps of 1500 GLs/per min.

FUEL SYSTEM

Total capacity of approx. 9000 ltrs.

02 Nos fibre glass integral hull tanks fitted to port and starboard sides of engine room aft, with fillers, vents, sight gauges and inspection covers. Tanks to be interconnected.

FRESH WATER SYSTEM

Total capacity approx 3000 Ltrs.

02 Nos. fibre glass integral hull tanks fitted to port and starboard sides of Aft peak with fillers, vents, sight gauges and inspection covers. Tanks to be interconnected.

Pressure water outlets to be provided at the Galley and toilet compartment.

ELECTRICAL SYSTEM

24 V DC system with 02 separate banks of 200 amp. Batteries for lighting and 2 x 100 amp batteries for engine start charged by the engine driven alternator. Separate banks for lighting and engine starting with paralleling and isolating facility. Power distribution to outlets through distribution box fitted with MCB.

Lighting consists of:

01 set navigation light

01 set navigation light  01 No. light Fore peak

01 No. light Fore peak  03 Nos. lights fwd accommodation

03 Nos. lights fwd accommodation  04 Nos. lights Engine room

04 Nos. lights Engine room  04 Nos. lights Wheel house

04 Nos. lights Wheel house  01 No. light Galley

01 No. light Galley  01 No. light Toilet

01 No. light Toilet  04 Nos. light Deck

04 Nos. light Deck  01 No Remote control search light

01 No Remote control search light

RUDDER AND STEERING SYSTEM

Rudder mechanism to be completed with mild steel skeg and rudder.

Rudder mechanism to be completed with mild steel skeg and rudder.  Stainless steel rudder stock fitted through GRP tube, bronze stuffing box and gland packing.

Stainless steel rudder stock fitted through GRP tube, bronze stuffing box and gland packing. An emergency tiller arm to be provided.

An emergency tiller arm to be provided. Wheel steering system to be of single station hand hydraulic type which helm pump and steering cylinder situated in the aft peak connected to rudder tiller arm.

Wheel steering system to be of single station hand hydraulic type which helm pump and steering cylinder situated in the aft peak connected to rudder tiller arm.

VENTILATION SYSTEM

Wheel house helm area - 03 Nos. front windows

Wheel house helm area - 03 Nos. front windows Wheel house accommodation area - 06 Nos. sliding windows

Wheel house accommodation area - 06 Nos. sliding windows  Fwd cabin - 08 Nos. Port lights

Fwd cabin - 08 Nos. Port lights  Window glass to be of heat reflective type Engine room - 02 Nos. 250 CFM extraction fans

Window glass to be of heat reflective type Engine room - 02 Nos. 250 CFM extraction fans Toilet - 01 No small extraction fan

Toilet - 01 No small extraction fan Galley - 01 No small extraction fan

Galley - 01 No small extraction fan

BOAT OPTIONALS

AIR CONDITIONING

Air conditioning system to be fitted for air conditioning of in side of wheel house and accommodation area below. Proposed Air conditioning equipments to be installed.

1x Sea water cooled liquid chiller (36000 Btu/Hr) with single compressor

1x Sea water cooled liquid chiller (36000 Btu/Hr) with single compressor  1x Digital display / Chiller control 1x Shielded Display cable (12m)

1x Digital display / Chiller control 1x Shielded Display cable (12m)  1x External air sensor with cable (12m)

1x External air sensor with cable (12m)  1x Chilled water circulation (Magnetic Drive) Pump

1x Chilled water circulation (Magnetic Drive) Pump  1x Sea water cooling (Magnetic Drive) Pump.

1x Sea water cooling (Magnetic Drive) Pump.  2x Chilled water compact air handler (12,000 Btu/Hr)

2x Chilled water compact air handler (12,000 Btu/Hr)  3x 3-Speed cabin blower control units.

3x 3-Speed cabin blower control units.

GENERATOR

22.5 KW / 60 Hz / 3 phase Marine Generator with sound shield installed. 9.3 ELECTRICAL OPTIONS 230 Volt /50 Hz emergency AC lighting system.

ELECTRICAL OPTIONS

230 Volt /50 Hz emergency AC lighting system.

CATHODIC PROTECTION

02 Nos. anodes of 2 Kg each are bolted to the underside of the hull adjacent to the stern gear and one on the rudder.

DECK FITTINGS

Stainless steel fwd Mooring bollard 02 Nos.

Stainless steel aft Mooring bollard 02 Nos.

Stainless steel pipe deck rail as shown on GA drawing Stainless steel pipe swimming platform

SAFETY & MISC. EQUIPMENTS

Magnetic compass (90 mm card dia.) 01 No

Magnetic compass (90 mm card dia.) 01 No  VHF Radio (Furuno Mdl FM 2721) 01 No

VHF Radio (Furuno Mdl FM 2721) 01 No

Life jackets 08 Nos.

Life jackets 08 Nos.  Life buoys 02 Nos.

Life buoys 02 Nos.  Fire extinguishers (1 Kg dry powder) 02 Nos.

Fire extinguishers (1 Kg dry powder) 02 Nos.  Anchor 01 No.

Anchor 01 No.  Anchor chain 10 Mtrs.

Anchor chain 10 Mtrs.  20 mm dia. Mooring rope 30 Mtrs.

20 mm dia. Mooring rope 30 Mtrs. Heavy duty windscreen wipers 03 Nos.

Heavy duty windscreen wipers 03 Nos.

PAINTING AND FINISHING

Exterior hull and deck to be finished to a perfect finish on molding and all interior visible to be leveled to smooth finish and painted over. Color as per customer request subject to availability of colours at the time of conformation of order. Hull bottom below water line to be antifouled.

TRIALS AND HANDING OVER

Exterior hull and deck to be finished to a perfect finish on molding and all interior visible to be leveled to smooth finish and painted over. Color as per customer request subject to availability of colours at the time of conformation of order. Hull bottom below water line to be antifouled.

WARRANTY PERIOD

Warranty period of one year is given on the vessel on any faulty material or workman ship and the manufactures warranty will be passed on to the customer on the equipment fitted on the vessel.

LAYOUTS

EXTERIOR/INTERIOR

http://neilmarine.com/index.php/18mtr-work-boat#sigFreeId22287e5f88

0

0 1

1 2

2